Soda lime glass or silica sand based standard glass represents 90% of glass offering. To form borosilicate glass we need to add boric acid (B2O3), alumina and soda ash to the silica melt. Low thermal expansion (3,3 × 10−6 K−1 ) is the main property of it. According to the SiO2 content and alkaline earth content there are three groups of B2O3.

The Non-alkaline-earth B2O3 group or borosilicate 3.3 has around 12% B2O3. The Alkaline-earth-borosilicate glasses group has less boric acid and SiO2 content and 5% of alkaline earth and/or alumina like the Aluminoborosilicate glass. The High-borate B2O3 contain 15 to 25% of B2O3, 65% to 70% of SiO2, and smaller amounts of alkalis and alumina and have low softening points and low thermal expansion but reduce chemical resistance.

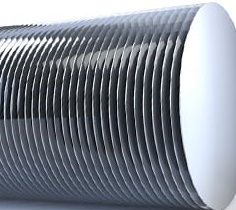

Photon Export proposes all borosilicate type of glass substrates from world leaders in specialty glass as Schott, Corning, GE, Ohara, Hearaus and HOYA. Any shapes, cuts and polishing specifications are made: from standard squares, to Silicon wafers or optical components for the photonics scientific researcher.

Technical Glass Substrates, borosilicate glass, Silicon Wafer & Crystals

Fused Silica, Silicon wafer, Sapphire crystal or other monocrystalline or polycrystalline crystals completes the substrates portfolio.