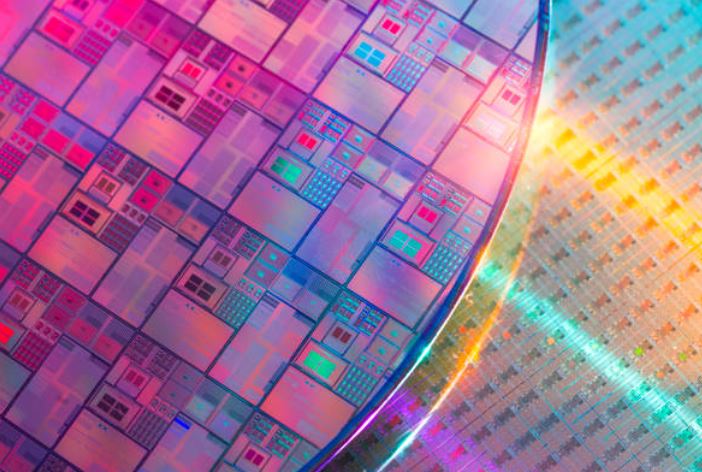

PhotonExport provides a wide range of wafers, including Silicon Wafers, Silicon Nitride, III-V, Crystal, Ceramic, Sapphire wafers, and more. Each with various specifications and coating options that can be tailored to your specific research and production needs.

Our offerings also include high-grade materials like Gallium Phosphide, Indium Arsenide, and Indium Gallium Arsenide, suitable for applications in infrared detectors, transistors, and integrated photonics. Learn more below or contact us for more details.

Silicon Wafers

PhotonExport offers a diverse range of silicon wafers and crystals, with specifications that include Single-Side Polished (SSP) and Double-Side Polished (DSP) options, thicknesses ranging from super-thin 2 microns up to thicker wafers or ingots, and doping options like P-type, N-type, or Undoped. Click the button below to learn more.

Silicon Nitride Wafers

PhotonExport provides Silicon Nitride Wafers, ideal for advanced research and production, featuring high resistance qualities and advanced LPCVD and PECVD coatings, available in sizes ranging from 2” to 12” to suit various industry applications.

III-V Wafers

PhotonExport offers high-grade III-V Wafers, including Gallium Phosphide, Indium Arsenide, Gallium Arsenide, and Indium Phosphide, tailored for both research and production needs.

Crystal Wafers

PhotonExport offers premium Crystal Wafers for scientific and technological applications, providing a wide range of orientations and sizes, including cubic, tetragonal, and hexagonal crystals, with high precision and custom options available.

Ceramic Wafers

PhotonExport offers high-quality ceramic wafers, including Alumina (Al2O3), Zirconia (ZrO2), and Aluminum Nitride (AlN) substrates, known for their exceptional mechanical strength, heat resistance, minimal dielectric loss, high abrasion resistance, and smooth surface.

Sapphire Wafers

PhotonExport offers Sapphire circle wafers: 0.5-inch to 8-inch. Square and rectangle sizes: 5 mm x 5 mm to 10 mm x 10 mm. If you need custom specifications please another size contact us today!

Indium Gallium Arsenide Wafers

We supply single crystal InGaAs:

- InGaAs is principally used for infrared detectors. Other applications include avalanche photo diodes, some of the fastest transistors, and photovoltaic triple-junction

Commonly supplied for your integrated photonics applications.