The quartz monitor crystal is essential for a quartz crystal-based measurement and control system.

What does a Quartz Crystal Monitor do?

The quartz monitor crystal is essential for a quartz crystal-based measurement and control system.

The crystal enables precise and repeatable thin film depositions.

Quartz crystal microbalance (QCMs) are microelectronic devices used in vacuum deposition chambers to measure the thickness of thin films on substrates. This is done by using the frequency response provided by the quartz crystal during the coating process. This frequency change can be associated to the quantity of coating material on the crystal surface.

Quartz crystals display thickness at the Ångström level (1 Angstrom is equivalent to 0.00000000393701 Inches or 0.0000001 Millimeters). Their level of precision and accuracy is significant because thickness deviations as little as 10 Angstroms can have a big effect on product performance.

The implication of this process to control system and its limitation is an important step for developing innovative and new products. The importance of quartz crystal sensors has been increasing in the past twenty years, since more advanced optical, electrical, and magnetic devices demand a sensor capable to process the right measurements.

Some of the industries that use this process in their production processes: optical, semiconductor, solar cell, and thin film display (OLED).

Get a longer live of your quartz monitor crystal by selection the appropriate electrode.

- 6MHz Quartz crystal sensors compatible with INFICON monitor, cotroller and microbalance.

- Size: 14 mm (0.550 in.)

- Frequency: 6 MHz

- 5MHz Quartz crystal also available.

- Size: 12.4 mm (0.489 in.)

- Frequency: 5 MHz

Electrode Chart Selection

| Electrode Material | Application Type | Electrode Chart Selection | Main Property |

|---|---|---|---|

| Gold | Standard | Infinite | Most common, adapted for most applications |

| Silver | Sputtering Type | Depends on oxidation and exposure to sulfur content in air (tarnishing effect) | Highest thermal conductance. Adapted when better heat transfer to cooled sensor body is needed. |

| Alloy | High Stress Coatings, Optical films, high stress semiconductor materials | Shorter than gold, two times more than Silver, with time alloy oxidize | Higher Activity values compared to Gold and Silver |

What is Quartz Crystal microbalance?

QCM (quartz crystal microbalance) sensors measure the mass variation per unit area by measuring the changes in the resonator frequency of a quartz crystal using its piezoelectric properties. Frequency changes linearly with the mass (or thickness). Quartz crystal monitoring systems are an essential component of the thin film deposition vacuum chambers, usually used in mass production.

It’s very important to control the temperature since the resonance frequency can change a lot with the temperature too. There are different types of crystals depending on its tolerance with the temperature.

Usually, work at the Ångström level (Order of 10-10). Little thickness deviations such as 10 or fewer Ångströms can have a major effect on the product performance. QCM sensor measurements have been improving more and more in the past years. Nowadays advanced optical, electrical, and magnetic devices require a process sensor capable of measuring layer thicknesses with 1 Ångstrom resolution reliably.

How does a typical QCM system work?

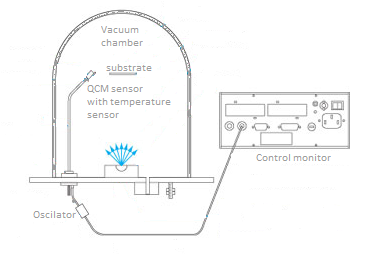

Inside the vacuum chamber, the sensor is placed near the substrate to measure the thickness of the film. It’s important to know its operating frequency range and the electrode quality of this crystal. The vacuum chamber must have a temperature controlled housing with the function of regulating the temperature of the sensor and its mechanical integrity.

Outside the chamber, an electric monitor creates a current which forces the crystal into vibration and tracks this frequency over time. It’s really important that this monitor can track accurately the crystal frequency changes and temperature characteristics. An internal microprocessor can convert this frequency changes in time to the actual thickness of the film.

What are the principal characteristics of the quartz crystals?

The crystal can have different electrode shape depending on the model system you are purchasing.

Physical Specifications of the crystal:

- Material : Pure Silicon Dioxide monocrystal

- Dimensions : 0.550” +. 000/.002” OD

- Contour : 2.5 – 3.0 diopter (212 – 177 mm radius of curvature) plano-convex

- Finish : 7 microns rms roughness plano and contour sides

- No chips, scratches or etch marks within a 13.95 mm diameter clear aperture

Electrical Specifications of the crystal:

- Available Frequencies : 5 and 6 MHz, fundamental series resonance

- Resistance : <10-15 Ohms

- Contact Resistance : <10 Ohms edge to edge on pattern side