What are Sensors & Feedthroughs?

Sensors and feedthroughs are essential components in thin film deposition and measurement systems. These elements work together to accurately monitor film thickness during coating processes, ensuring both stability and efficiency. At Photonexport, we supply top-quality sensors and feedthroughs, offering reliable and cost-effective solutions to meet the specific requirements of your thin film applications.

Sensors

Sensors play a crucial role in real-time film thickness measurement using Quartz Crystal Microbalance (QCM) technology. By detecting frequency changes during deposition, they enable precise control over coating rates. This is vital in industries like semiconductor manufacturing, optics, and thin film displays, where accuracy is non-negotiable.

At Photonexport, we offer a variety of sensors designed for different applications. Whether for standard coatings or highly specialized processes, our solutions ensure consistent and precise performance, optimizing your production workflow.

Feedthroughs

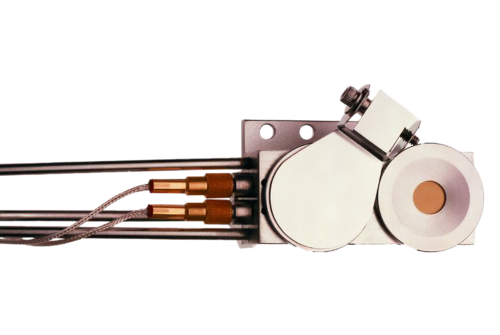

Feedthroughs are responsible for maintaining vacuum integrity while linking internal sensors with external monitoring equipment. They provide stable data transmission and ensure seamless operation throughout the deposition cycle.

Photonexport supplies durable, high-performance feedthroughs designed for secure connections and easy maintenance. Our solutions help reduce downtime and enhance overall system efficiency, making them an essential part of any advanced thin film process.

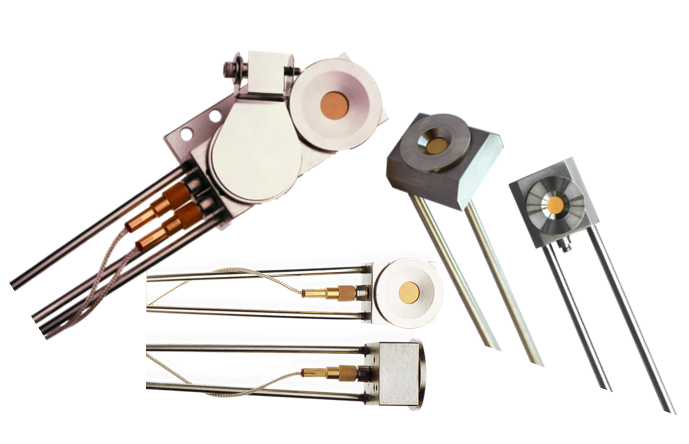

Types of Sensors and Feedthroughs

At Photonexport, we offer a variety of sensors and feedthroughs designed to meet the diverse needs of thin film deposition systems. Whether you’re using single sensors for standard applications or dual sensors for more critical processes, our products provide high performance and reliability.

We also supply different feedthrough designs, tailored to accommodate your specific system requirements. Our feedthroughs ensure smooth integration, maintaining the necessary vacuum conditions while supporting seamless data transmission.

Why Choose Our Sensors & Feedthroughs?

- High Accuracy and Precision:

Our monitoring tools offer real-time measurement of thin film thickness, essential for controlling deposition rates with precision. Whether for optical coatings or batch processes, these solutions deliver consistent, reliable data to achieve high-quality results.

- Durability and Low Maintenance

The sensors we supply are designed for long-term use with minimal maintenance. This results in reduced operational costs, as their sturdy construction minimizes downtime and ensures dependable performance in demanding environments.

- Versatile Applications

Our products are suitable for industries such as semiconductor manufacturing, solar panel production, and research labs. Whether you need solutions for high-precision applications or general monitoring, we have the right options for your needs.

- Seamless Integration and Easy Installation

These sensors and feedthroughs integrate smoothly into existing systems. With various configuration options—such as standard and right-angle orientations—these components offer flexibility for different setups and operational environments.

- Cutting-edge Technology

We offer components equipped with advanced technologies like Quartz Crystal Microbalance (QCM) and ModeLock technology. These innovations guarantee reliable and precise measurements for various thin film applications.

- Feedthrough Compatibility

Our feedthroughs ensure stable data transmission while preserving the integrity of the vacuum environment. With multiple designs available, including options with or without bored-through tube fittings, we provide solutions that match your system’s requirements.

By choosing our high-quality sensors and feedthroughs, you can optimize your thin film deposition processes, improve product quality, and enhance overall system performance.

Explore our product range today to find the perfect sensor and feedthrough solutions for your specific application

Sensors & Feedthroughs

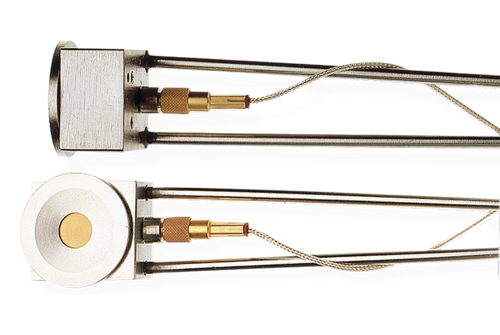

A cost-effective and reliable solution for high-accuracy thin-film thickness monitoring. Designed for short optical and batch coating processes, it minimizes production costs while ensuring long-lasting performance with minimal maintenance. Available in standard and right-angle configurations for flexible integration.

A durable and high-precision sensor with exceptional thermal stability, ensuring accurate and consistent thin-film deposition. Its front-load design allows easy crystal replacement, making it ideal for applications with limited space. Designed for reliability and longevity in demanding coating environments.

A reliable dual-crystal sensor designed for critical thin-film deposition processes. With a built-in backup crystal, it ensures continuous monitoring and minimizes downtime. Its front-load design allows easy crystal replacement, making it ideal for high-precision applications requiring uninterrupted performance.