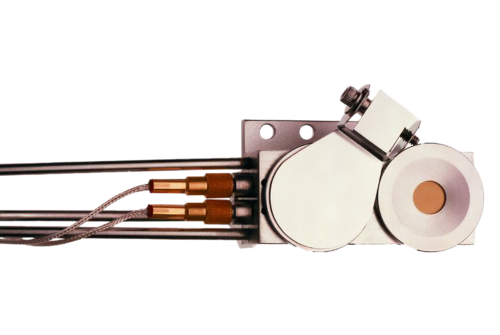

Front Load Dual Sensor

The Front Load Dual Sensor is engineered for exceptional accuracy, reliability, and durability, making it an ideal choice for critical thin-film deposition processes. With its dual-crystal configuration, this sensor ensures continuous operation, as the backup crystal activates automatically when the primary crystal reaches its lifespan. This feature is essential for high-precision coating applications, minimizing interruptions and maintaining consistent process efficiency.

Effortless Installation & Seamless Integration

The front load design simplifies the insertion of the crystal holder, particularly in tight spaces where side insertion is not feasible. This space-saving feature enhances flexibility in various system setups, making it easy to integrate into both new and existing vacuum deposition systems.

Durable, Modular & Low-Maintenance Design

Unlike soldered alternatives, the Front Load Dual Sensor is mechanically assembled, allowing for quick and hassle-free part replacements when necessary. This modular design significantly reduces downtime, ensuring that your production line remains efficient and uninterrupted. The sensor’s robust construction provides long-term durability, minimizing the need for frequent maintenance while delivering consistent, high-quality measurement performance.

Flexible Installation Options for Maximum Compatibility

This high-performance sensor is available individually or as part of a sensor/feedthrough combination, offering customized solutions based on specific installation requirements. With options for welding or compression fittings, it seamlessly integrates with various vacuum deposition systems, ensuring maximum process adaptability.

Optimized for High-Precision Applications

Designed for thin-film monitoring in advanced manufacturing environments, the Front Load Dual Sensor supports demanding coating applications, including optical coatings, semiconductor processing, and precision industrial coatings. Its dual-crystal functionality provides a cost-effective solution, reducing the need for frequent manual interventions and improving overall system productivity.

Whether you are upgrading an existing setup or designing a new vacuum deposition process, the Front Load Dual Sensor delivers the stability, accuracy, and efficiency required to achieve superior deposition results with minimal maintenance requirements.

Features

- Dual crystals

- Crystal shutter

- Front load crystal holder

- Easy installation

- Available with: 2.54 cm (1 inch) bolt feedthrough and CF40 feedthrough

- Adjustable length if ordered with compression fittings

- No brazing required if ordered with compression fittings or welded to feedthrough

- Sensor/feedthrough combinations available welded to customer specified lengths

Front Load Dual Sensor Specifications:

| Maximum operating isothermal environment temperature with minimum water flow | 400°C |

| Crystal exchange | Front-loading, self-contained package for ease of exchange. Shutter flips up to ease access to the holders. |

| Water tubes | S-304, 0.125 in. (3.175 mm) OD x 0.015 in. (0.381 mm) Wall thickness seamless stainless steel tubing |

| Feedthrough Specifications 1 in. bolt and Ultra-Torr (compression fitting) terminations: | |

| Materials | 304 stainless steel, Teflon, ceramic, beryllium nickel, VITON® |

| Temperature | Operational environment to 300ºC with water cooling or 165° C without |

| Mounting | 1.015 in. ±0.010 in. diameter aperture |

For Full Specifications

PDF • 716 KB

Accessories

Accessories

| Name | Description |

| QCM Sensor Feedthroughs | QCM Sensor Feedthroughs |

Consumables

| Name | Description |

| Quartz Monitor Crystals | Quartz Monitor Crystals |

Spare Parts

| Part Number | Description |

| 007-007 | Retainer spring (for crystal holder) |

| 007-023 | Ceramic Retainer |

| 080-018 | Set screw (for female coax) |

| 082-044 | Teflon screw (for leaf spring) |

| 750-115-P4 | Coupling (installs onto bellows assembly) |

| 750-169-P2 | Bellows assembly (coupling not included) |

| 750-171-P1 | Finger spring contact |

| 750-172-G1 | Crystal holder (includes retainer spring) |

| 750-174-P2 | Female coax |

| 750-175-P1 | Insulator (underneath leaf spring) |

| 008-007 | CRYSTAL SNATCHER |

| 750-188-P3 | Leaf Spring |

| 750-210-G1 | Shutter module (bellows assembly, shaft assembly, and shutter assembly) |

| 750-215-G1 | Shaft assembly (part of shutter module) |

| 750-216-G1 | Shutter assembly (part of shutter module)In-vacuum cables |

| 321-039-G12 | In-vacuum cable, 15.2 cm (6 in.) |

| 783-500-023 | In-vacuum cable, 25.4 cm (10 in.) |

| 007-252 | In-vacuum cable, 30.5 cm (12 in.) |

| 321-039-G11 | In-vacuum cable, 61.0 cm (24 in.) |

| 007-044 | In-vacuum cable, 78.1 cm (30.75 in.) |

| 007-059 | In-vacuum cable, 91.4 cm (36 in.) |

| 007-061 | In-vacuum cable, 121.9 cm (48 in.) – Requires ModeLock controller |

| 007-061 | In-vacuum cable, 121.9 cm (48 in.) – Requires ModeLock controller |

| 321-039-G13 | In-Vacuum Cable, 154.2 cm (60 in.) – Requires ModeLock controller |

| 321-039-G14 | In-vacuum cable, 182.9 cm (72 in.) – Requires ModeLock controller |

| 321-039-G15 | In-vacuum cable, 3.5 m (137.8 in.) – Requires ModeLock controller and 4 m XIU |

| 321-039-G16 | In-vacuum cable, 4 m (157.5 in.) – Requires ModeLock controller and 4 m XIU |

Others

Application Note – Shuttered Crystal Sensor

PDF • 121,3 KB • ENGLISH

What is a QCM Sensor?

PDF • 531,6 KB • ENGLISH

For detailed pricing or to learn more about how the Front Load Dual Sensor can benefit your specific needs, feel free to reach out to us.