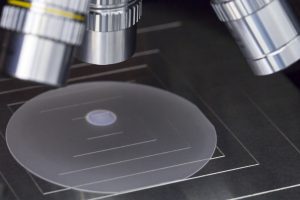

Our wafer selection includes sapphire wafers that have excellent physical and chemical properties which makes them invaluable feature for a range of hi-tech applications.

Sapphire substrates are highly regarded in the LED industry for their reliability, abundance and cost efficiency.

Sapphire Wafer Specifications

- Orientation: Synthetic sapphire can be grown in all common crystal orientations including “A”, “C”, “R”, “M” plane.

- Primary flat Orientation: C-plane (0001), A-plane (11-20), M-plane(10-10), R-plane(1-102), N-plane(11-23), V-plane(22-43), (10-14).

- Circle wafers: 0.5-inch wafer to 8-inch wafer. If you need another size contact us.

- Square and rectangle wafers: 5 mm x 5 mm, 10 mm x 10 mm. If you need another size contact us.

- Surface finishing: Both single side polish (SSP) and Double side polish (DSP) are possible.

Sapphire Windows

- Sapphire Windows are manufactured from single crystal sapphire, making them ideal for demanding applications because of their extreme surface hardness and high thermal conductivity.

- Diameter ranging from 3.5 mm to 290 mm or also square sizes ranging from 3 mm x 3 mm to 200 mm x 200 mm.

- Any orientation and thickness are possible. Sapphire windows can be custom coated.

Patterned Sapphire Substrates (PSS)

- Patterned Sapphire Substrates have a micro-patterned mainly use for LED applications.

- PSS are available from 2 inch diameter to 4 inch diameter. Pattern sizes and shape can be of a diameter of 2.7 +/- 0.1 μm, and a spacing of 0.3 +/- 0.1 μm and a depth of 1.7 +/- 0.15 μm.

Sapphire Ingots

- Ingots are cut from high-grade Kyropoulos grown boules with a high purity of 99.999%. With or without flat.

Note: The standard for measuring the quality of sapphire crystal are FWHM (full width at half maximum) and EPD.

What are the methods for fabricating single crystal sapphire?

Nowadays, there are several methods of fabrication single crystal sapphire counting Kyropoulos method, Edge-defined film-fed Growth (EFG) method, and Heat Exchanger Method (HEM). These methods deliver sapphire with different specifications such as size, thickness, and inclusions.

What is the Kyropoulos Method:

This growth technique fits for synthetic sapphire with low thermal conductivity and a high degree of thermal expansion.

The Kyropoulos method yields large-diameter sapphire boules of outstanding optical quality due to its high purity.

What is the Heat exchange method (HEM):

HEM method create synthetic Sapphire with outstanding transmission and homogeneity. Due to its high optical transmission, low transmitted wavefront distortion and outstanding mechanical-strength properties, HEM Sapphire is widely used for high-precision sapphire windows to deliver high levels of performance and reliability.

What is the Horizontally Directed Crystallization (HDC):

The method of Horizontally Directed Crystallization (HDC) is often used in the synthesis of large sapphire monocrystals. The elements of the directed crystallization and zonal melting are successfully combined in the Horizontally Directed Crystallization (HDC) method. The crystal grows at slow movement of the local melted zone along the container with the furnace charge, having a boat form. The HDC method provides receiving of monocrystalline sapphire with small sizes dispersion of cross section and allows to grow up sapphire monocrystal of any crystallographic orientation in the form of plates of the record sizes unattainable at use of other growth methods.

Stepanova Method or Edge-defined film-fed growth (EFG):

The EFG method, or melt extraction or crystal pulling, is a single crystal growing technique for synthesizing pure, monocrystalline materials. The EFG method provides the capacity to get several shapes such as sapphire substrates for integrated circuits, sapphire single crystals with predefined diameter and sapphire tubes for laser and high-pressure Na lamps.