Sputtering Target bonding services

Bonding Services by PhotonExport helps ensure the optimal performance of your sputtering target.

Properly bonding the target to a suitable backing plate is essential to prevent cracking, warping, and inadequate cooling.

At PhotonExport, we provide expert metallic bonding and elastomer bonding services to ensure superior thermal and mechanical integrity, unlocking the full potential of your sputtering process. Trust us to deliver exceptional results.

The thermal and mechanical integrity of the bond between the backing plate and the sputtering target is critical in order to provide optimal sputtering performance. We offer metallic bonding and elastomer bonding services.

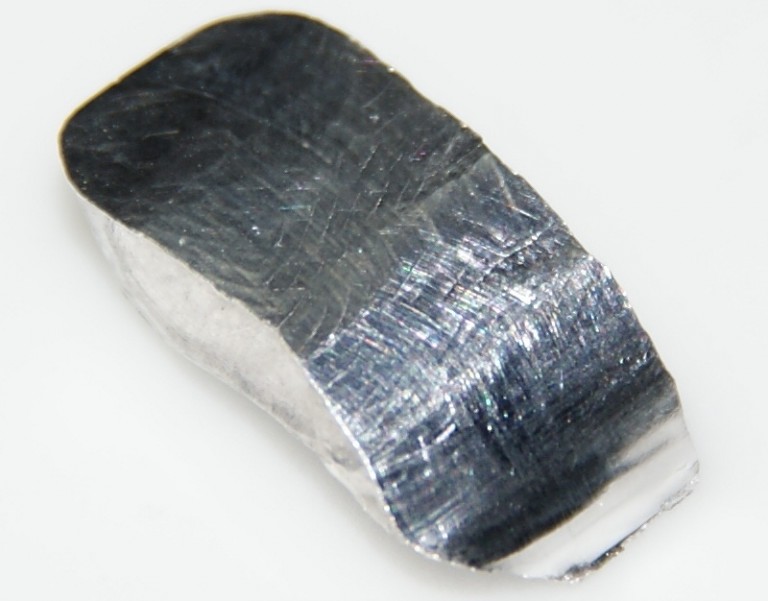

Indium bonding for Sputter Targets

Indium bonding is considered a soldering process. It operates at temperatures of 170 degrees Celsius and is the preferred method for bonding sputtering targets with the best thermal conductivity. This process is highly efficient at dissipating heat from the target. Cracking is also reduced, thanks to the softer solder that allows for some flexibility if the target expands at a different relative rate compared to the backing plate. The relatively low melting point of 156.6 degrees Celcius is the main limitation of this solder, as temperatures above 150 degrees Celcius will provoke melting and failure of the bond.

The rear side metallization of substrates results in a void-free bond with high reliability. The Tri-Layer coating offers excellent adhesion to all substrates, and the resulting barrier layer prevents undesirable alloying with the Iridium. The result is improved adhesion and enhanced thermal conductivity.

Key advantages include: low melting point, ability to creep and remove stress as dissimilar materials cool and reduced warpage.

Elastomer bonding for Sputter Targets

Elastomer is an alternative to other bonding systems with several outstanding benefits that have allowed for its acceptance in the industry.

The benefits include:

- Bond reproducibility is assured through the precise handling and dispensing of the elastomer bond material.

- Controlled uniformity and distribution of the elastomer bond.

- Creates a reliable joint between most material combinations.

- Provides a stress-free assembly in application.

- The ductility of the elastomer bond enables bonding of dissimilar materials.

- Suited for bonding of fragile materials.

- Bonds are electrically conductive.