There are many types of perovskite mineral, however the most commonly used type of perovskite in the solar energy industry is methylammonium lead halide perovskite (CH3NH3PbX3, X5I, Cl, Br). It is characterized by high light absorption coefficient, which covers the highest energy band of solar spectrum (from 280 nm to 2000 nm). Perovskites are semiconductors with an organometallic halide or oxide structure used to transport electric charge, whenever the light hits the material. A cell with the perovskite crystal is called Perovskite solar cells (PSC).

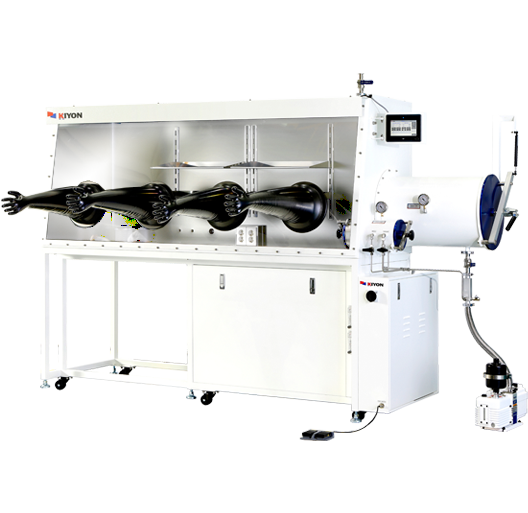

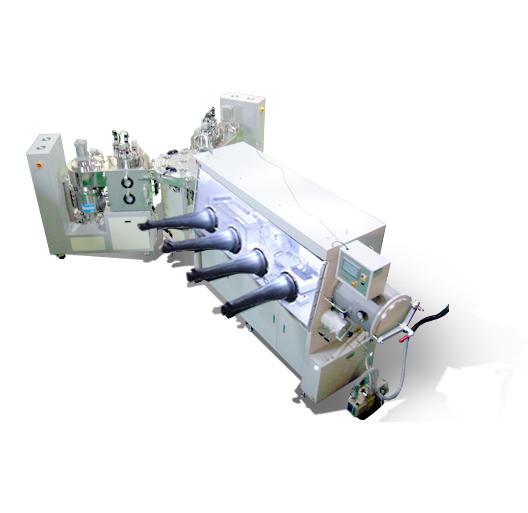

PhotonExport provides Gloveboxes and Spin Coating needed for PSC processing.

PSC High Efficiency

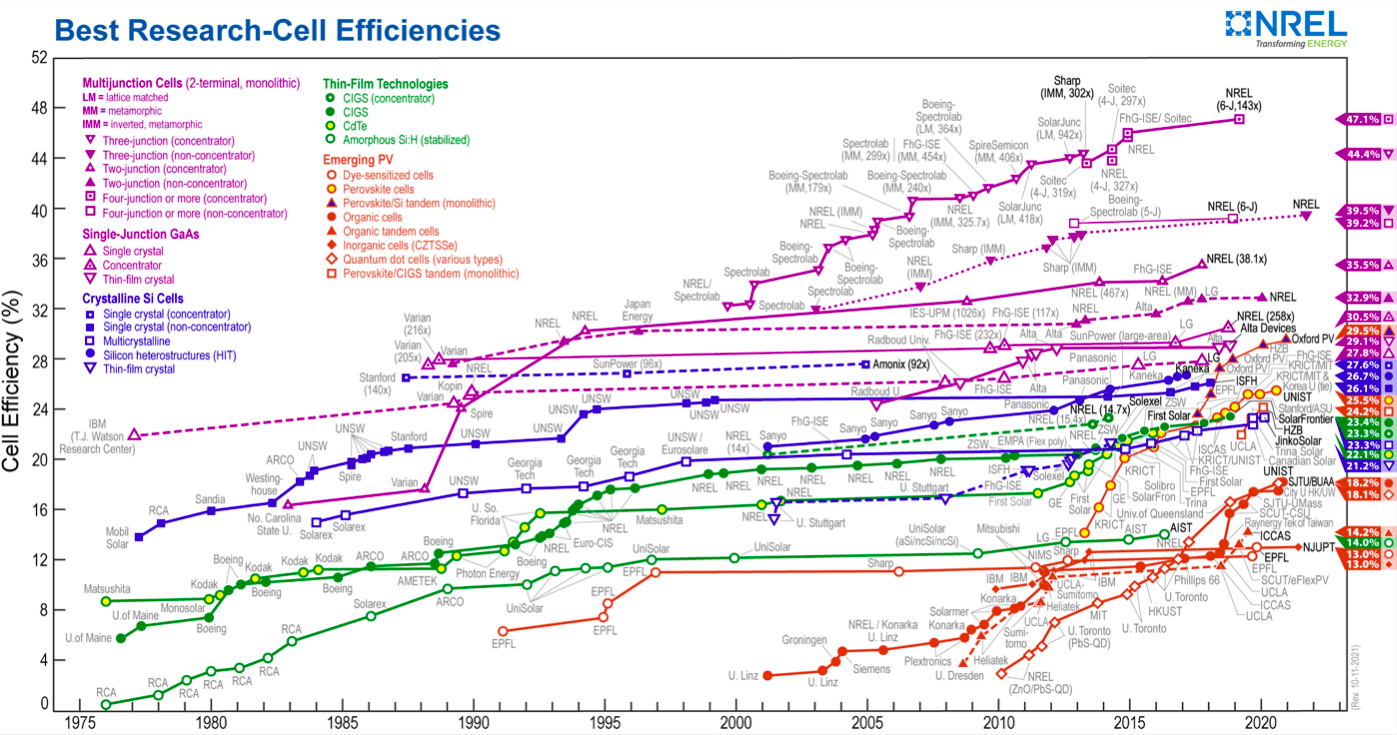

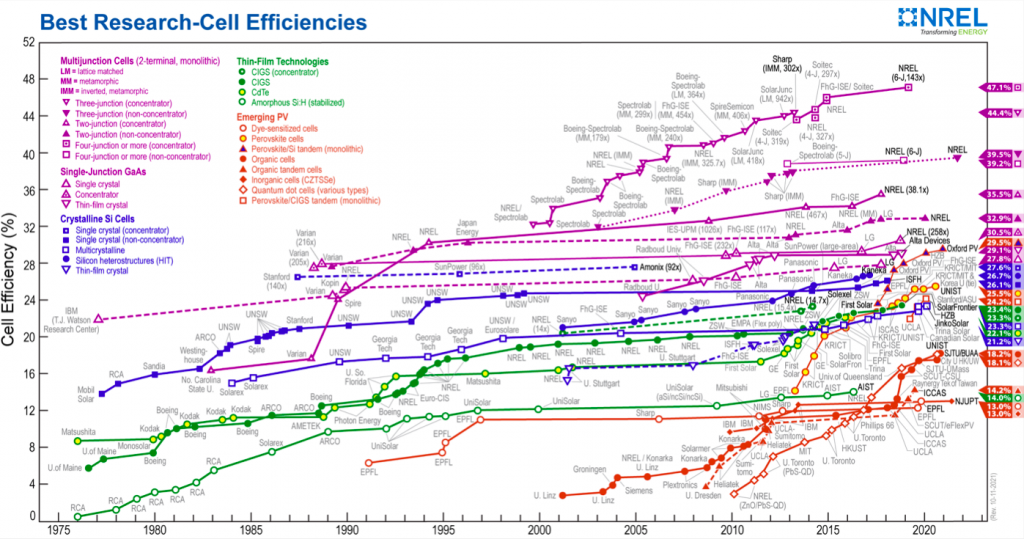

The of efficiency Perovskite solar cell has also emerged as one of the most standout cell (figure 1).

1. Efficiency chart of Perovskite solar cell (PSC) LINK

PSC Advantages

Perovskite solar cell have attracted great attention due to its advantageous features including lightweight, semi transparency and flexibility. Also ease of fabrication, low production cost (table 1), and rapidly–improving device efficiencies are some of valuable proportion of PSC.

| Characteristics | CdTe | CIGS | c–Si | Perovskite |

| Efficiency | Medium | Medium | High | High |

| Energy payback period | Medium | High | High | Low |

| Fabrication cost | Medium | Medium | High | Low |

| Finished material cost | Low | High | High | Low |

| Levelized cost of electricity | Medium | High | High | Low |

| Raw material cost | Low | Medium | Low | Low |

Table 1. Comparison of PSC with thin–film solar cells

Major Advantages of the PSC

- Response to different wavelengths of light, which permits PSC to charge over a greater amount of daylight

- Energy utilization– perovskite based solar cells demonstrate a low loss

- Perovskite–based powered cells offer adaptability, semi transparency, tailored from factors, lightweight ect.

*One sun is defined to be equivalent to the irradiance of one solar constant, and the solar constant is defined as the irradiance of the sun on the outer atmosphere at a distance of 1 AU.

| Characteristics | a–Si | c–Si | III/V | Perovskite |

| One sun performance* | low | high | high | high |

| Low light performance | high | low | high | high |

| Power/cost ratio | medium | high | low | high |

| Free-from design options | medium | low | medium | high |

Table 2. Comparison of PSC with thin–film solar cells

Solution Processing Method

Solution processing is one of the key advantages of PSC due to the good solubility therefore certain low–cost processing techniques such as spray coating, spin coating, screen coating, and thermal evaporation can be applied. Those techniques often require an oxygen and moisture free environment, which can be provide by purified glove boxes with control of O2 and H2O level. KOREA KIYON Gloveboxes, distributed by PhotonExport ensure safety and technical aspects of inert atmosphere needed in this processing step.

Spray pyrolysis is commonly used in PSC production, where the material is deposited on the substrate by spraying solutions. The unstable material is removed from the coating layer at the working temperature. All the properties of the material are dependent on temperature, which make this type of technology very effective.

Spin–coating, which is widely used in the field of organic electronics, is one of the most suitable high–speed processing techniques for the production of PSC. This process is based on the deposition of the solution on the substrate by rapid rotation and very consistent drying, resulting in the formation of PSC. PhotonExport offers different models of spin coaters with a wide range of options.

One of the most efficient processes for making PSC is the dip coating method. The base of the solution is immersed in the solution for effective formation of the material. After the material has deposited, the substrate is removed by evaporation, which makes the thickness of the layer exceptional.

Although this method is not included in the solution processing technique, it will play a major role in the production of PSC. To produce the perovskite, the material is directly deposited in the vapor phase. Single–layer deposition technique and the multilayer deposition technique are the two most commonly used thermal evaporation techniques. The single–layer deposition method is based on the process of the inorganic perovskite deposition material is evaporated which is placed on the sheet of metal. The multi–layer deposition method involves the evaporation of inorganic and organic salts, and an annealing process is required in the post–production process. PhotonExport can help you source the right PVD equipment and supply the best equipment and products for your unique needs.

Challenges for Processing Method

Over the past 50 years, many industries have developed dramatically. The gap between the automotive and electronics industries is huge. Why did photovoltaics stop in the 70s (figure 2)?

|

|

|

|

|

|

Figure 2. Development of the photovoltaic industry– 1970 vs today

The major challenge of PSC is that the components of PV degrade rapidly in the perovskite cell architecture and charge extraction.

One of the greatest challenges in the field of perovskite research is the stability of the devices during their lifetime. The efficiency of cells powered by perovskite is close to the given values of efficiency currently leading technologies of monolithic crystals e.g. GaAs and silicon.

Another main challenges in extracting energy from perovskite cells is the presence of lead. Perovskite utilizes dangerous lead, which leads to concern for the environment as well as the degeneration of materials. This high–performance perovskite produces high air humidity. Moisture will cause a domino effect of decomposition, therefore the PV properties of the perovskite material will lose. In order to protect the environment and the person working with perovskites, glove boxes are widely used to protect against the harmful effects of lead. PhotonExport distributes a wide range of standard and customized, high quality KOREA KIYON gloveboxes.