Thin film technology is crucial in precision manufacturing, allowing for the deposition of extremely thin material layers across various surfaces. At Photonexport, we offer high-precision thin film deposition solutions that cater to industries that require advanced coatings and accurate layer control. Our product range includes essential tools for managing deposition rates and ensuring consistent material layering, such as the Quartz Crystal Microbalance (QCM).

By integrating these precision measurement tools into the deposition process, manufacturers can gain complete control over the application of thin films. These tools are designed to deliver the accuracy and consistency needed in critical industries, including semiconductors, optics, and advanced materials. The use of QCM technology ensures that even the most intricate and delicate thin films are applied with exact precision.

Photonexport’s tools not only enhance the quality of thin film deposition but also provide real-time process feedback. This allows for dynamic adjustments to deposition parameters, resulting in greater process efficiency, reduced waste, and improved product quality. Our dedication to delivering innovative thin film technology solutions helps drive manufacturing excellence and reliability.

Monitors

Monitors are crucial components in the thin film deposition process. At Photonexport, we offer high-quality monitors that allow you to accurately track deposition rates, thicknesses, and other critical parameters. These monitors provide real-time data throughout your processes, helping to enhance production efficiency. Our monitors ensure the precise application of thin film layers, especially in sensitive applications like semiconductors, optics, and energy systems.

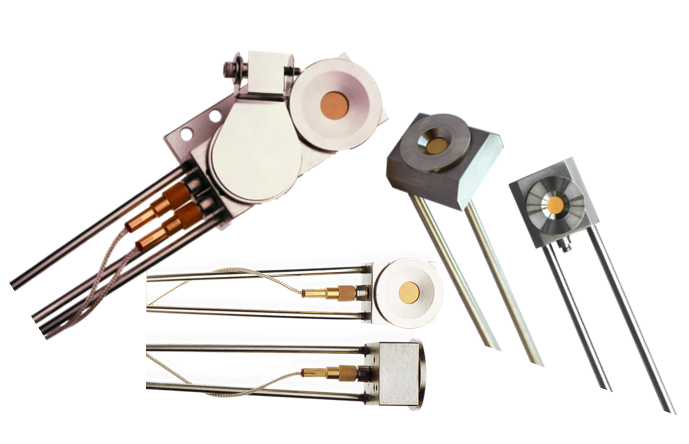

Sensors & Feedthrough

Sensors & Feedthroughs are critical for ensuring the precision and reliability of thin film deposition processes. At Photonexport, we offer advanced sensors and feedthrough solutions from the most trusted industry brands, which monitor essential parameters such as pressure, temperature, and gas flow. These components help maintain the optimal environment during deposition, enabling real-time control of processes and ensuring the accurate and consistent quality of films. The sensors and feedthroughs we provide are designed for demanding environments, offering high performance and durability, especially in applications like semiconductor and optical coating processes, where precision is paramount.

Controllers

Thin Film Deposition Controllers are crucial for ensuring precise control over the deposition process, maintaining consistency and accuracy. At Photonexport, we offer a range of high-quality deposition controllers that help manage deposition rate, thickness, and layer processes efficiently. These controllers, including advanced models like the XTC/3, are designed for both single and multi-layer applications, ensuring reliable results across various industries.

As distributors of leading thin film deposition controllers, we provide our customers with easy-to-use solutions that enhance productivity, minimize errors, and optimize deposition performance. With advanced features like automated sensor switching and high reliability, our controllers are essential for both research and industrial applications.

Quartz Crystal Monitor

The Quartz Crystal Monitor (QCM) is an essential tool for accurately measuring film thickness in thin film deposition processes. By utilizing the piezoelectric properties of quartz crystals, QCM monitors changes in frequency to measure the buildup of material on a substrate. This technology is widely used in industries requiring high precision, such as semiconductors, optics, solar panels, and OLED displays.

QCM systems operate in vacuum chambers, providing real-time feedback during the coating process. This allows for immediate adjustments, ensuring uniform and precise film thickness. With the ability to measure with an accuracy of up to 1 Ångström, QCMs help improve product quality, reduce waste, and lower production costs.